Research

The 3D Print Lab sees itself as a service provider and research platform for data visualization and additive manufacturing processes. We are an interdisciplinary team of surgeons, radiologists and medical engineers with the aim of finding new forms of presentation and applications for three-dimensional image data. The starting point for this is the long-standing expertise of the Department of Oral and Maxillofacial Surgery, where 3D models are already routinely used today.

3D models produced by us also support other surgical disciplines in surgical planning and are also used for patient education. In addition, 3D-printed image data is used in teaching and training.

As an institution within the University Hospital Basel, we are an active research platform and are available as a project partner.

Further information can be found on the website of the Department of Biomedical Engineering.

3D-Printed in-house PEEK Implants: Revolutionizing Surgery

Witness the future of surgical innovation as we introduce 3D-printed PEEK implants. This groundbreaking technology, developed in-house, promises a new era of personalized and efficient medicine at the University Hospital Basel.

In August 2023, history was made when a patient received our 3D-printed PEEK implant, manufactured right here at University Hospital Basel. This achievement is a testament to years of research and development by our experts."

Learn our patient's journey and our cutting-edge process:

Ready to explore the potential of 3D-printed PEEK implants? Reach out to us for consultations and inquiries.

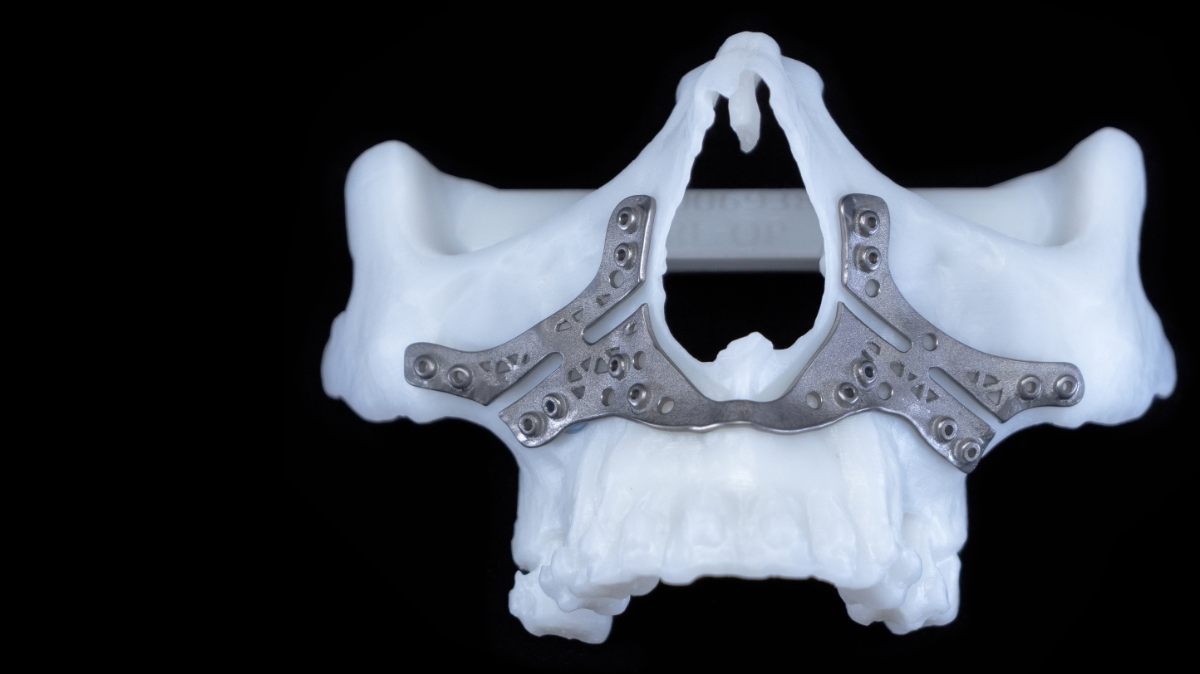

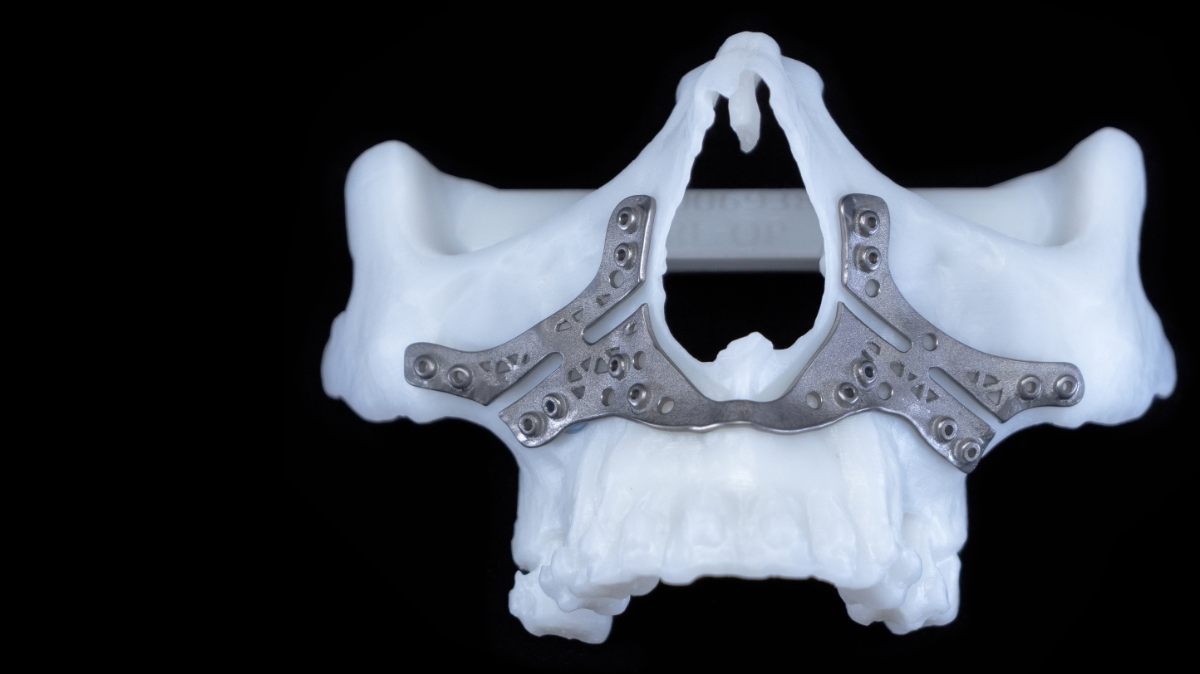

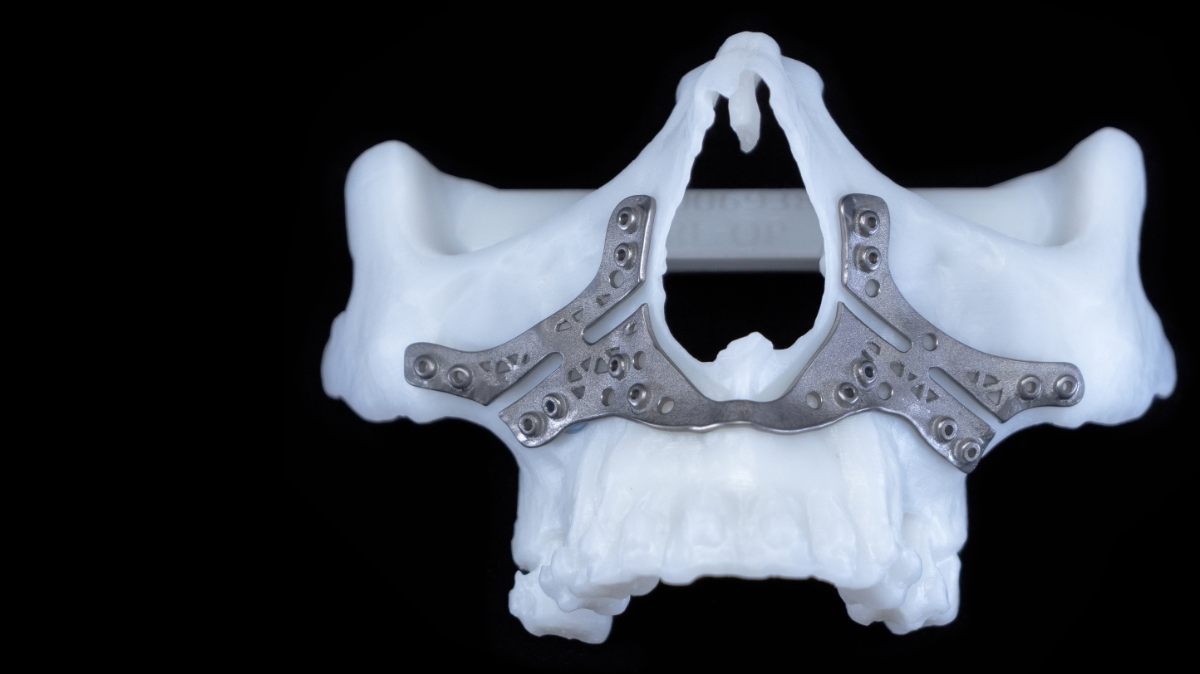

Surgical Guides: Precision in Every Incision

Imagine having a 3D map for your osteotomies, tailor-made for every patient. Our cutting guides are designed to optimize fibula reconstructions, craniotomies, and other common procedures, where precise cutting through the hard tissues are required. They provide surgeons with a roadmap, ensuring implants and medical devices are latter placed with pinpoint accuracy.

From Digital to Reality: Our process seamlessly integrates CT or MRI image data acquisition with virtual planning. By integrating this data, we can specifically outline the future shape of the planned cuts and we can design a device which highlights with these limits, while taking into account the patients' unique anatomy. After design, we can bring these cutting guides to life by using a 3D Printing procedure called Vat Polymerization, which uses a high-precision laser to cure liquid resin, layer by layer, in order to create intricate and accurate 3D models. The resins used in this procedure are biocompatible, which ensure optimal patient safety.

Ready to explore the potential of Surgical Guides? Reach out to us for consultations, inquiries, or to experience a demonstration of this surgical revolution.

Personalized anatomical models: Unveiling the Human Body in 3D

Imagine a world where medical professionals can hold a patient's unique anatomy in their hands, gaining unprecedented insights and honing their skills, diagnostics and procedures with absolute precision. Welcome to the future of medical education and practice, courtesy of 3D Printed Personalized Anatomical Models.

In order to bring these anatomical models to life, we incorporate patient specific CT/MRI data of the targeted area with an array of 3D printing procedures. From the most basic, to the most complex manufacturing procedure, we are starting of with Multi-Color Fused Deposition Modeling (FDM), which enables us to use biodegradable thermoplastic materials, that are selectively melted and deposited in order to create the anatomical models, in a layer by layer method. This process enables the production of low-cost, multi-colored models, which can be recycled when they are no longer needed.

Binder Jetting is a game-changer in the realm of 3D printing. This technique combines speed and precision to produce anatomical models that defy convention. By selectively binding layers of gypsum, it brings personalized anatomical models to life swiftly and accurately, making them accessible for a wide range of medical applications, when supports are desired on the surface of the models and the models are not subjected to severe handling conditions.

Material Jetting is the pinnacle of 3D printing technology, delivering anatomical models that are nothing short of masterpieces. With the ability to print multiple materials in a single pass, it allows for the creation of highly detailed, multilayered structures. This technique enables the recreation of not only the visual aspects but also the tactile feel of human anatomy, providing an immersive learning experience like never before.

Not sure which type of procedure you require for your anatomical models? Reach out to us for consultations and inquiries.

Training models: Elevate Medical Training in a safe environment

Develop a learning environment where medical students and professionals can practice, refine, and perfect their skills with our 3D printed training models. By encompassing our 3D modeling skills with our 3D printing production capabilities, we can develop accurate and realistic training models, to simulate the specific pathologies or training with specific surgical devices. Our in house developed training models can be produced in a plethora of materials, by combining several 3D printing tehnologies.

Ready to sharpen your surgical skills with our precision training models? Cut through uncertainty with our expert guidance. Reach out for consultations and inquiries today.