Offer 3D Print Lab

We are pioneers in the dynamic field of medical 3D printing. Using state-of-the-art technology, we transform image data from patients into tangible solutions that are specifically tailored to your individual needs. Our services include the creation of personalized anatomical models, surgical templates, custom-made prostheses and the in-house production of implants.

If you would like information about our price list, please contact us.

3D scanning

We offer comprehensive 3D scanning of physical objects, dental models or anatomical segments into high-resolution 3D models. We use state-of-the-art technologies to scan objects and convert them into digital representations, enabling a wide range of applications in various industries.

Segmentation of CT and/or MRI data

Our experts specialize in extracting precise data from CT and/or MRI scans to enable accurate diagnosis and treatment planning. We convert complex medical images into 3D models, ensuring medical professionals have the information they need to provide optimal patient care.

Anatomical models

We create highly detailed anatomical models from the patient's image data. These 3D representations are valuable tools for surgical planning, patient education and a better understanding of complex medical conditions, which ultimately leads to better patient outcomes and shorter operating times.

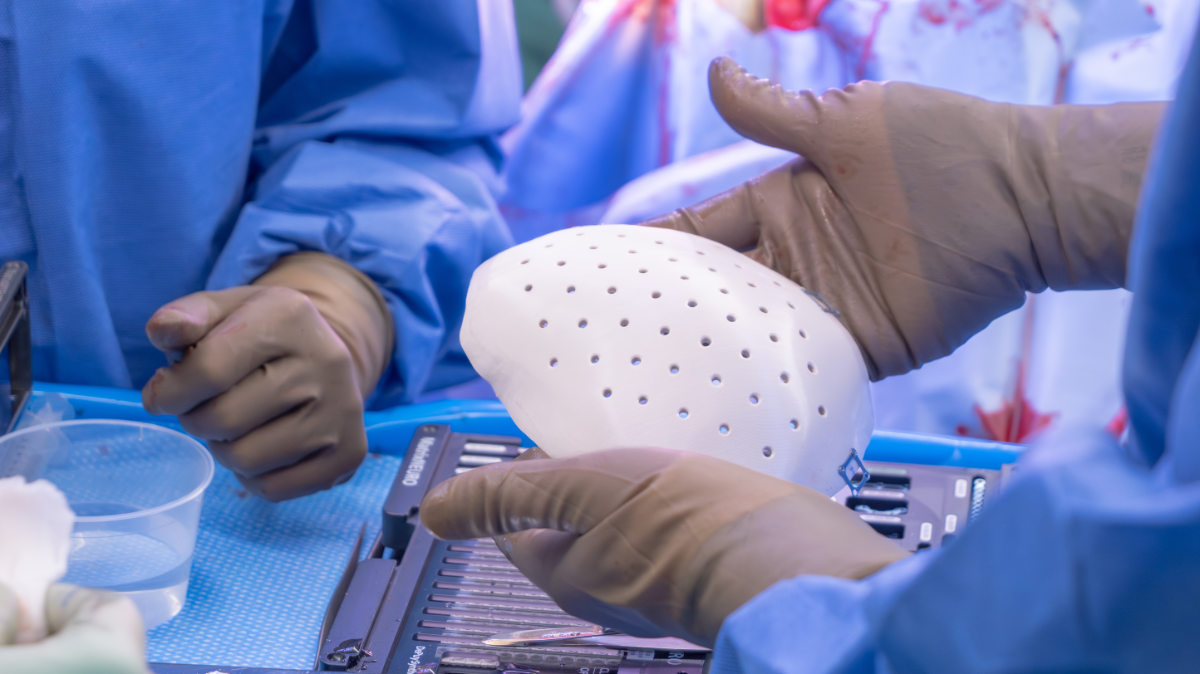

Our own 3D-printed PEEK implants: Revolutionizing surgery

Experience the future of surgical innovation as we introduce 3D-printed PEEK implants. This groundbreaking, in-house developed technology promises a new era of personalized and efficient medicine at the University Hospital Basel.

In August 2023, history was made when a patient received our 3D-printed PEEK implant, manufactured right here at University Hospital Basel. This achievement is a testament to the years of research and development by our experts."

Surgical guidelines: precision in every operation

Imagine having a 3D map for your osteotomies that is customized for each patient. Our cutting templates are designed to optimize fibula reconstructions, craniotomies and other common procedures that require precise cuts through hard tissue. They provide the surgeon with a roadmap to ensure implants and medical devices are placed with pinpoint accuracy.

From digital to reality: Our process seamlessly integrates the acquisition of CT or MRI image data with virtual planning. By integrating this data, we can accurately outline the future shape of the planned incisions and design a device that emphasizes these boundaries, taking into account the patient's unique anatomy. Once designed, we can bring these incision guides to life using a 3D printing process called vat polymerization. In this process, a high-precision laser hardens liquid resin layer by layer to create intricate and accurate 3D models. The resins used in this process are biocompatible, which ensures optimal patient safety.

Personalized anatomical models: decoding the human body in 3D

Imagine a world where medical professionals can hold a patient's unique anatomy in their hands, gaining unprecedented insight and refining their skills, diagnoses and procedures with absolute precision. Welcome to the future of medical education and practice, courtesy of 3D-printed personalized anatomical models.

To bring these anatomical models to life, we integrate patient-specific CT/MRI data of the target area with a range of 3D printing techniques. From the simplest to the most complex manufacturing process, we start with multi-color fused deposition modeling (FDM), which allows us to use biodegradable thermoplastic materials that are selectively melted and deposited to create the anatomical models layer by layer. This process enables the production of cost-effective, multi-colored models that can be recycled when they are no longer needed.

Binder jetting is a novelty in the field of 3D printing. This technique combines speed and precision to create anatomical models that defy convention. By selectively binding plaster layers, personalized anatomical models are brought to life quickly and accurately, making them accessible for a variety of medical applications where supports on the surface of the models are desired and the models are not subjected to heavy handling conditions.

Material jetting is the pinnacle of 3D printing technology, delivering anatomical models that are nothing short of masterpieces. With the ability to print multiple materials in a single pass, highly detailed, multi-layered structures can be created. This technique makes it possible to recreate not only the visual aspects but also the tactile feel of the human anatomy, providing an unprecedented learning experience.

Training models: Advanced medical training in a safe environment

Develop a learning environment where medical students and professionals can practice, refine and perfect their skills with our 3D printed training models. By combining our 3D modeling capabilities with our 3D printing production capabilities, we can develop accurate and realistic training models to simulate specific pathologies or train with specific surgical devices. Our in-house developed training models can be produced in a variety of materials by combining different 3D printing technologies.

Virtual operation planning

Virtual surgical planning is the future of precision medicine. We offer state-of-the-art simulations that allow surgeons to rehearse procedures in a risk-free virtual environment. This advanced technology improves surgical precision, reduces complications and promotes confidence in the operating room.

Our team designs customized surgical guides and implants tailored to individual patient needs. These precision-engineered instruments improve surgical procedures, reduce risks and promote better surgical outcomes.